Stamping parts and brackets

- High carbon steel (1050-1090)

- Low carbon steel (1008-1018)

- Stainless Steel (T-430, T-301,T-302, T-304)

Materials can be of round or rectangular shapes, according to the customer’s needs.

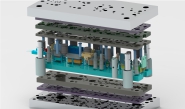

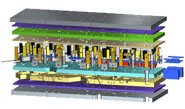

We are specialists in high-precision progressive stamping and manufacture internally all of our toolkits.

- Our stamping capacity

- goes from 20 to 300 tons force.

- Our maximum workbench capacity is

- 94.5″ X 47.2″/ 2400mm X 1198mm

Zinc, Nickel, Phosphate, Tin, Silver, Delta-Tone, E-coat, Magni, Passivated, Paint, Rust-prevent oil.

All the coatings we offer are compliant with the environmental standards of the automotive industry and can stand up to 720 test hours in saline chamber.

- Special packaging

- Cleaning tests and measurement of dust particles.

- Heat treatments a/o stress relieving.

- 100% automated sorting and inspection

- Automated burr removal